In 2024, AI factories will revolutionize manufacturing. The post 2024 is all about AI Factories appeared first on Analytics India Magazine.

In 2023, AI revolutionized manufacturing operations by automating costly processes. In 2024, AI factories will revolutionize manufacturing by managing and analyzing data from sensors, boosting productivity, quality, and setup costs through technologies like NVIDIA Tesla in the cloud.

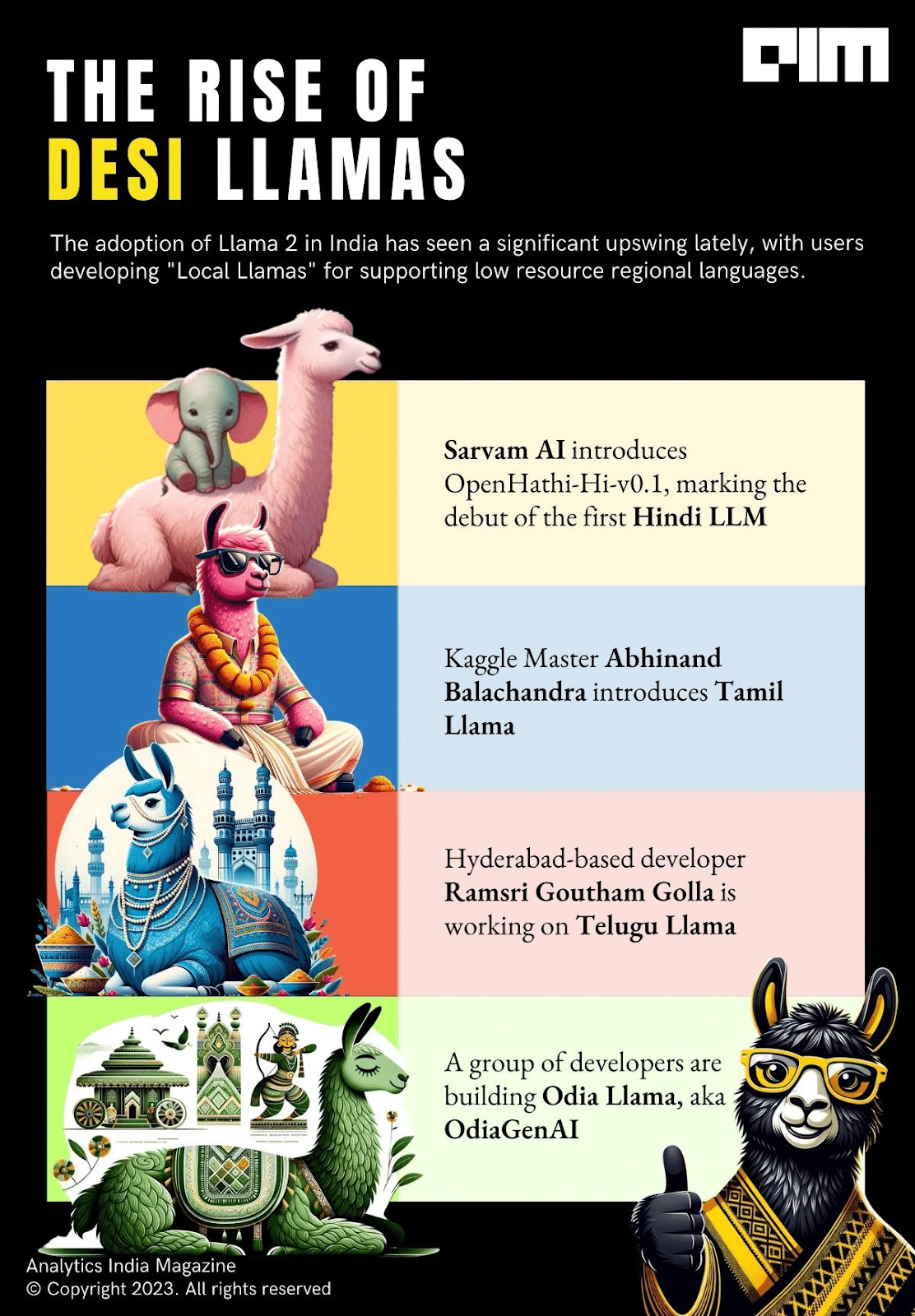

Here are some of the examples:

NVIDIA x Foxconn

Foxconn recently announced partnering with NVIDIA to develop AI factories, a GPU computing infrastructure for processing and transforming vast amounts of data into valuable AI models and tokens. The partnership will also include the development of smart solution platforms like Foxconn Smart EV, built on NVIDIA DRIVE Hyperion 9, NVIDIA DRIVE Thor, NVIDIA Isaac autonomous mobile robot platform, and Foxconn Smart City, which incorporates the NVIDIA Metropolis intelligent video analytics platform.

The aim is to help the industry move faster into the new AI era, as stated by Foxconn Chairman and CEO Young Liu. Key NVIDIA technologies used include NVIDIA HGX reference designs, NVIDIA GH200 Superchips, NVIDIA OVX reference designs, and NVIDIA networking. Foxconn is also considering its own AI factory, using the NVIDIA Omniverse platform and Isaac and Metropolis frameworks to meet strict production and quality standards in the electronics industry.

NVIDIA x BMW

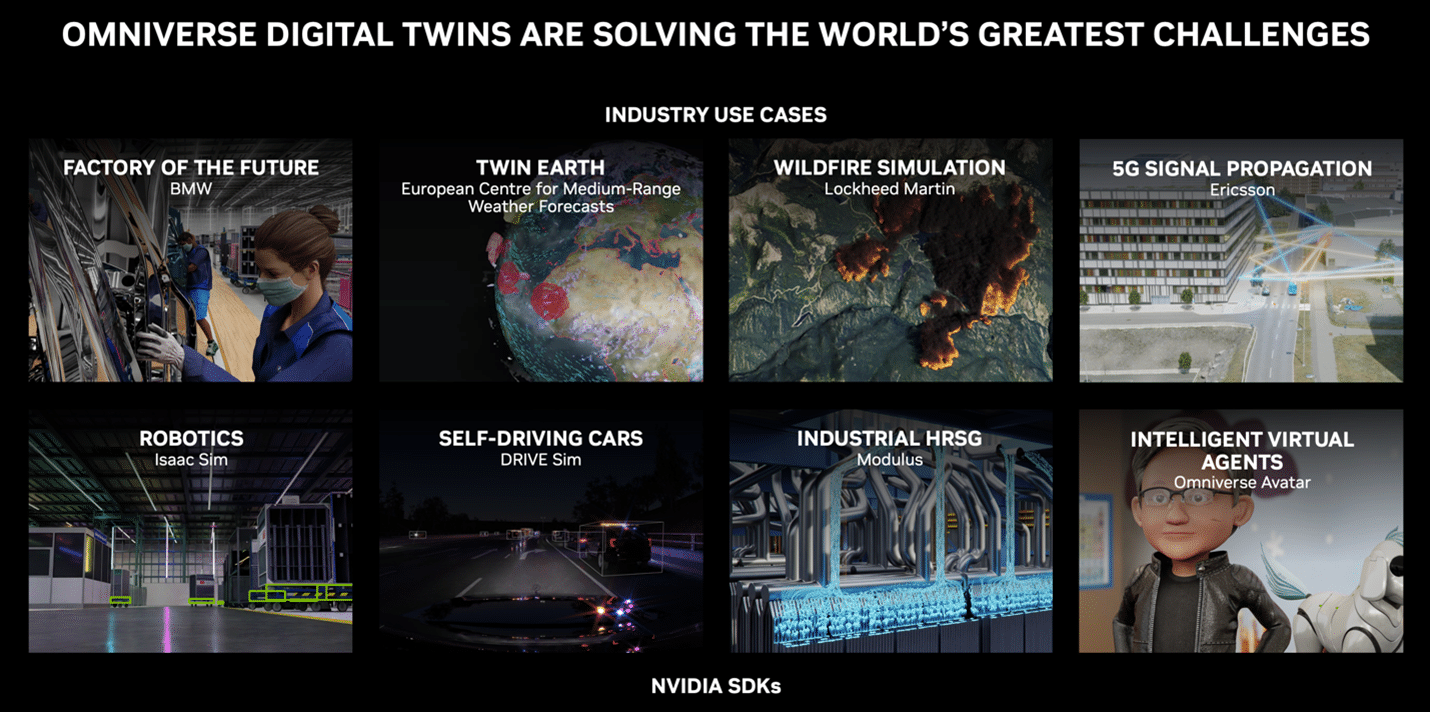

NVIDIA CEO Jensen Huang presented a vision of the future of manufacturing factories, blending reality, virtual reality, robotics, and AI to manage BMW’s automotive factories. The AI factory demo showcased the NVIDIA Omniverse Enterprise, the first technology platform enabling global 3D design teams to work simultaneously across multiple software suites in a shared virtual space. The AI factory demo included the NVIDIA Isaac platform for robotics, the NVIDIA EGX edge computing platform, and the NVIDIA Aerial software development kit.

BMW’s factory lines can produce up to 10 different cars, with over 100 options for each car and more than 40 BMW models. The technology revolutionizes BMW’s planning processes, allowing workers to work in a perfect simulation without having to travel. The use of NVIDIA Omniverse and NVIDIA AI allows for the simulation of 31 factories in a production network, enabling AI-enabled use cases such as virtual factory planning, autonomous robots, predictive maintenance, and big data analytics.

NVIDIA x SIEMENS

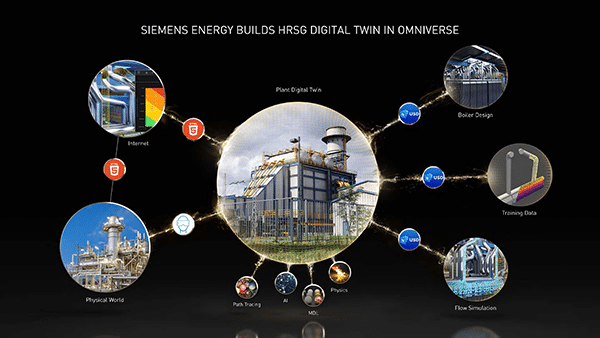

Siemens Energy, a leading supplier of power plant technology, is using the NVIDIA Omniverse platform to create digital twins for predictive maintenance of power plants. This is part of a wave of companies using digital twins to enhance their operations, including BMW Group and Ericsson. The global market for digital twin platforms is forecasted to reach $86 billion by 2028. Siemens Energy builds and services combined cycle power plants, including gas and steam turbines.

A 10% reduction in the industry’s average planned downtime for heat recovery steam generators could save $1.7 billion a year. Siemens Energy is using NVIDIA technology to develop a workflow to reduce planned shutdowns while maintaining safety. Real-time data is preprocessed to compute pressure, temperature, and velocity of water and steam, which is fed into a physics-ML model created with the NVIDIA Modulus framework. The flow conditions are visualized using NVIDIA Omniverse, a virtual world simulation and collaboration platform for 3D workflows. This helps Siemens Energy fine-tune maintenance needs without running the risk of failure.

The post 2024 is all about AI Factories appeared first on Analytics India Magazine.