A truck customization shop expanded their capabilities by offering AutomationDirect PLCs and HMIs to control expansive on-vehicle lighting displays. Just as many car owners like to customize their rides, there is a growing convoy of truck operators who like...

A truck customization shop expanded their capabilities by offering AutomationDirect PLCs and HMIs to control expansive on-vehicle lighting displays.

Just as many car owners like to customize their rides, there is a growing convoy of truck operators who like to do the same as a personal and promotional statement. Dickerson Custom Trucks has been catering to this market for 15 years. The founder, Dustin Dickerson, wrote an article for Machine Design November 2023 titled A Technology Upgrade for Trucking Chicken Lights, describing how his team added the ability to automate LED lighting systems to their toolkit.

Tailor-Made Trucks

Dickerson Custom Trucks operates under a “built, not bought” motto. As there has been an accelerating demand for big rig customization beyond mechanical upgrades and paintwork, they have looked for additional ways to serve their clients.

LED lighting products have made it easier than ever to install more and brighter lights on vehicles and trailers. Older style marker/clearance lights were incandescent and just a single DOT color such as red or amber, but newer versions are brilliant LED that can be operated either dim or bright, with a secondary/additional alternate color, such as green, blue, purple, pink, and white. The team knew they could install elaborate light arrays, but it needed a way to automate them.

Road-Worthy Automation

While the Dickerson technicians are skilled in many fields, no one was familiar with automation or programming. A bit of investigation revealed that industrial-grade PLCs and HMIs would be an excellent fit for this work, and the team quickly zeroed in on the AutomationDirect CLICK PLC and C-more HMIs as having the proper form factor, electrical ratings, and programming features.

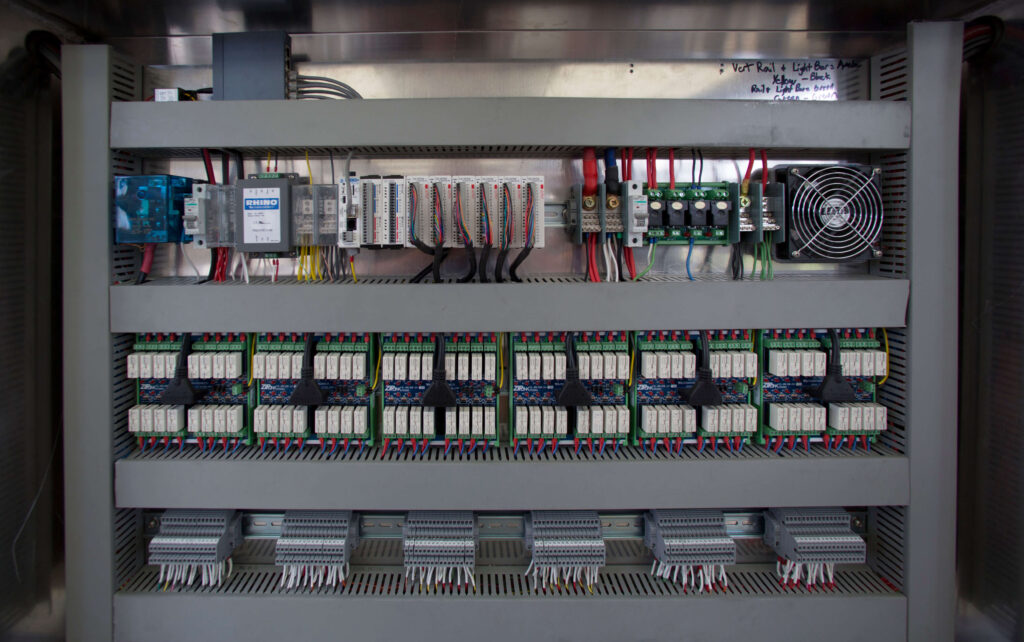

In fact, the team was able to easily procure all the control panel parts they needed from AutomationDirect, including ZIPLink cables/connectors, Rhino power components, and more. They quickly assembled the control panel, and then installed approximately three miles of wiring to support over 100 lights on each side of the trailer.

Putting On A Show

Using the AutomationDirect website product support, and with a little assistance from a knowledgeable friend, the team discovered how straightforward the free PLC and HMI development environments were, and they started developing their first basic program. All code was written in ladder logic, and used standard drum sequencer instructions, as an efficient way of driving the light patterns.

Automating big rig trailer lighting is just the first step for the shop. Based on the positive experience, they plan to expand PLC/HMI technology into other aspects of their work and they now have complete flexibility to automate whatever they choose.

The team at Dickerson was excited to add AutomationDirect-based lighting automation into their portfolio of capabilities because it differentiates them from other shops by expanding the range of projects they can perform for their customers.

Visit the AutomationDirect.com website today to explore how easy-to-use automation projects can help transition your custom projects from dreams to reality.

All figures courtesy of Dickerson Custom Trucks