IVISYS machine vision solutions merge cutting edge usage of hardware with in-house developed software, clever algorithms, and neural networks (AI). The post How PALLETAI makes a difference appeared first on IVISYS.

It’s all about our true passion for high tech that enables high impact.

IVISYS machine vision solutions merge cutting edge usage of hardware with in-house developed software, clever algorithms, and neural networks (AI). IVISYS pallet inspection solution, the PALLETAI, increase the warehouse efficiency and the logistics automation in the whole supply chain. It has a huge impact of the warehouse flow and provides you with real time data.

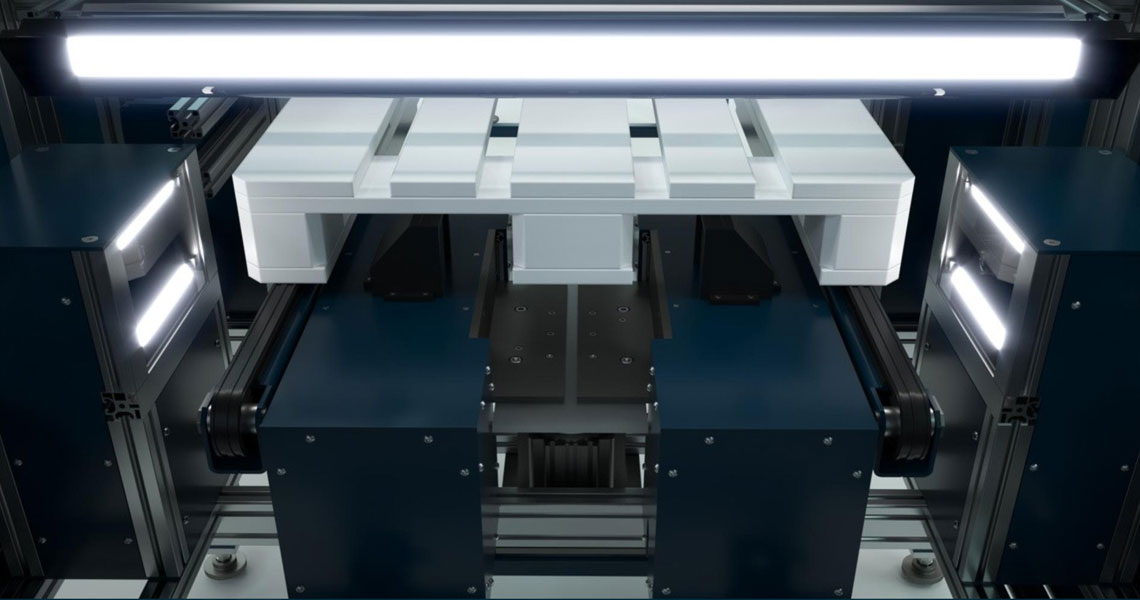

Our PALLETAI in short.

Our PALLETAI solution offers peace of mind so you can focus on production, uptime, efficiency in your production, logistics or warehouse chain. In addition to this the PALLETAI enables safety for both employees, the loaded goods, and the warehouse. The PALLETAI helps you avoid space waste, load imbalance, stop in production, and material loss and can be used for both wooden and plastic pallets as well as being applied to nearly all pallet configurations.

PALLETAI – a turn-key solution

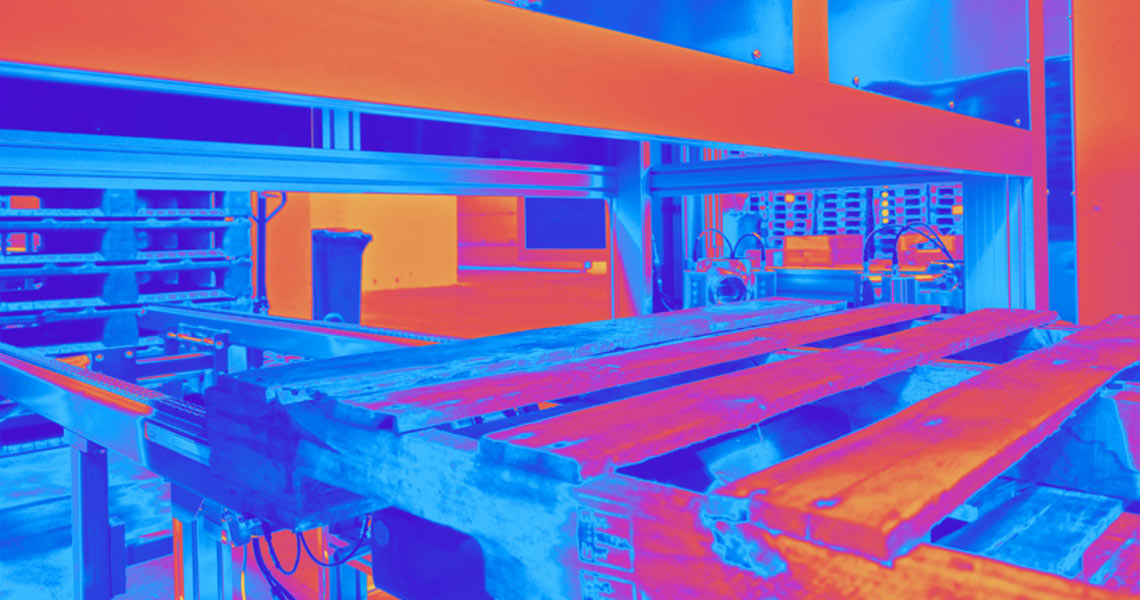

The PALLETAI is a turnkey solution with great flexibility in a variety of pallets and sorting fractions. The PALLETAI can be retrofit into your existing production line or established as a stand alone sorting cell. The PALLETAI is a scalable, flexible and modular solution that can be integrated in your facility without taking up too much space. The capacity of inspecting pallets and what defects to inspect; the sorting criteria’s, are all based on your needs. The PALLETAI can be a fully automated solution with several robots and lines or placed as a stand-alone sorting cell.

PALLETAI – contributes to a sustainable world

Our PALLETAI makes it easier for you to contribute to a greener, more sustainable world by reducing CO2 footprint. Reusable pallets are all valuable assets needing to be quality assured after every use. With the help of our automated pallet inspection system, the PALLETAI, detection of defects and faults is done effectively and quickly, ensuring higher quality of the pallet. We can detect pallets that are no good to use or pallets that need repairing.

PALLETAI – is The future of inspection and provides

Unlimited uptime

The PALLETAI allows running your sorting operation continuously 24/7 and it never becomes fatigued.

Increased capacity

The PALLETAI increases your sorting capacity up to fivefold compared to a human operator.

Collecting data

The PALLETAI keeps track of which suppliers that are delivering goods on pallets of lesser quality.

Defects our PALLETAI can detect.

Dimensional accuracy of the pallet (LxWxH) Protruding nails Cracks in boards & blocks Sorting based on appearance Missing, broken or dislocated boards or blocks Blocked tunnels Logo detection & verification Plastic/paper residueTop 10 PALLETAI insights

The PALLETAI can be retrofitted into an existing sorting line It can be applied in new automated warehouse operations Inspects both wooden and plastic pallets Works with nearly all pallet configurations Scalable performance with a modular, flexible solution Insource the sorting process to allow savings on managed recovery pallets Rejection and sorting based on defect type and your specific needs Real-time monitoring data and statistics Reports with data, statistics and analysis Service agreement & sparepart kit availableTop line benefits

Correctly graded pallets Increased uptime, productivity, efficiency and ROI Less defects, increased quality Safe employees, goods and retail chain Contributes to a more sustainable worldDoes it sound too good to be true? It’s not.

IVISYS PALLETAI is a smart hack for your success.

The post How PALLETAI makes a difference appeared first on IVISYS.