While RFID technology has been around for almost 70 years, the last decade has seen widespread acceptance, particularly in automated manufacturing. It is now deployed for various common applications, including automatic data transfer in machining operations, quality control in...

While RFID technology has been around for almost 70 years, the last decade has seen widespread acceptance, particularly in automated manufacturing. It is now deployed for various common applications, including automatic data transfer in machining operations, quality control in production, logistics traceability, and inventory control.

While RFID technology has been around for almost 70 years, the last decade has seen widespread acceptance, particularly in automated manufacturing. It is now deployed for various common applications, including automatic data transfer in machining operations, quality control in production, logistics traceability, and inventory control.

RFID has contributed significantly to the evolution of data collection and handling. With this evolution has come vast amounts of data which can be crucial for process improvement, quality assurance, and regulatory compliance. Nevertheless, many organizations grapple with the challenge of transforming this abundance of data into actional insights.

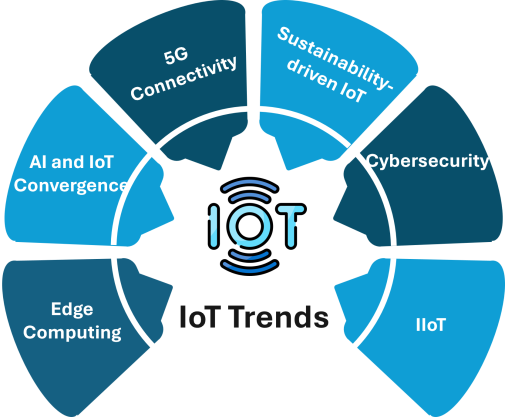

Key industry terms such as Industry 4.0 and the Industrial Internet of Things (IIOT) were once perceived as distant concepts crafted by marketing teams, seemingly disconnected from the practicalities of the plant floor. However, these buzzwords emerged as a response to manufacturing organizations worldwide recognizing the imperative for enhanced visibility into their operations. While automation hardware and supporting infrastructure have swiftly progressed in response to this demand, there remains a significant need for software that can effectively transform raw data into actionable data. This software must offer interactive feedback through reporting, dashboards, and real-time indicators.

Key industry terms such as Industry 4.0 and the Industrial Internet of Things (IIOT) were once perceived as distant concepts crafted by marketing teams, seemingly disconnected from the practicalities of the plant floor. However, these buzzwords emerged as a response to manufacturing organizations worldwide recognizing the imperative for enhanced visibility into their operations. While automation hardware and supporting infrastructure have swiftly progressed in response to this demand, there remains a significant need for software that can effectively transform raw data into actionable data. This software must offer interactive feedback through reporting, dashboards, and real-time indicators.

Meeting the demand will bring vendors from various industries and start-ups, with a few established players in automation rising to the occasion. Competition serves as a motivator, but the crucial factor in bridging the software gap on the plant floor lies in partnering with a vendor attuned to the specific needs of that environment. The question then becomes: How do you discern the contenders from the pretenders? The following is a checklist to help.

Does the potential vendor have:

A solid understanding that downtime and scrap must be reduced or eliminated? Core expertise in automation tailored for the plant floor? Smart hardware devices such as RFID and condition monitoring sensors? A comprehensive system solution capable of collecting, analyzing, and transporting data from the device to the cloud? A user-friendly interface that allows interaction with mobile devices like tablets and phones? The ability to generate customized reports tailored to your organization’s requirements? A stellar industry reputation for quality and reliability? A support chain covering pre-sales, installation, and post-sales support? Demonstrated instances of successful system deployments? A willingness to develop or adapt existing devices to address your specific needs?If you can tick all of these, it’s a safe bet you are in good hands. Otherwise, you’re taking a chance.

The post Transforming Big Data Into Practical Insights appeared first on AUTOMATION INSIGHTS.