Here we go the unsung heroes of your vehicle’s safety – brake pads. They’re not just stopping your car; they’re halting a spinning metal disc every time you brake. Imagine that, repeated for thousands of miles without complaint. Learn...

Here we go the unsung heroes of your vehicle’s safety – brake pads. They’re not just stopping your car; they’re halting a spinning metal disc every time you brake.

Imagine that, repeated for thousands of miles without complaint. Learn about What Is a Brake Pad and How It Works including their care and how to spot signs of wear. Your brakes shouldn’t take a break – ensure they’re always up to the task of keeping you and others safe on the road!

If you want to watch the video please see on YOUTUBE.

The History of Brake Pad Technology

Before the 1890s, cars navigated the roads with wooden block brakes. The driver’s act of pushing a lever caused these blocks to rub against the wheels, creating friction and, subsequently, slowing down the vehicle. However, as speeds increased, and wheels became more complex, wooden block brakes proved inefficient.

In 1898, Elmer Ambrose Sperry’s innovation changed the landscape of braking systems. The introduction of front-wheel disc brakes, paired with brake pads that “pinched” the rotor, mirrored the mechanics of bicycle brakes. This breakthrough laid the foundation for modern brake pad technology.

Over time, brake pad technology saw various milestones. The invention of brake linings, bonded with brake pads by Bertha Benz in 1888, played a crucial role. In 1918, Malcolm Loughead’s introduction of a four-wheel brake system using hydraulics became a standard by the end of the 1920s. Additionally, Frederick W. Lanchester’s patent for disc brakes in 1902 paved the way for further advancements.

How Today’s Brake Pad Works

Today, your vehicle’s braking system is a complex interplay of components, with brake pads playing a pivotal role. When you press the brake pedal, a cylinder is activated, sending brake fluid through hoses to the calipers.

The calipers, in turn, engage the brake pads. These brake pads apply pressure to the rotor, directly connected to each wheel. The resulting friction slows or stops the vehicle. Releasing the brake pedal initiates the reverse process: the brake pads release, brake fluid returns through the hoses, and the wheels are in motion again.

Calipers and rotors are integral to the brake pad system. Calipers, activated by hydraulic pressure, serve as the mechanism to engage the brake pads. The rotor, connected to each wheel, bears the brunt of the pressure from the brake pads, creating the necessary friction for deceleration.

The friction itself is actually the fundamental principle behind brake pads. As the brake pads apply pressure to the rotor, the resulting friction slows down the rotor, and consequently, the wheels. This friction-based mechanism is crucial for the safe operation of your vehicle.

Upon releasing the brake pedal, the brake pads retract, brake fluid returns to its origin, and the vehicle is ready to move again. This seamless reversal process underscores the reliability and efficiency of modern brake pad systems. That’s how it works.

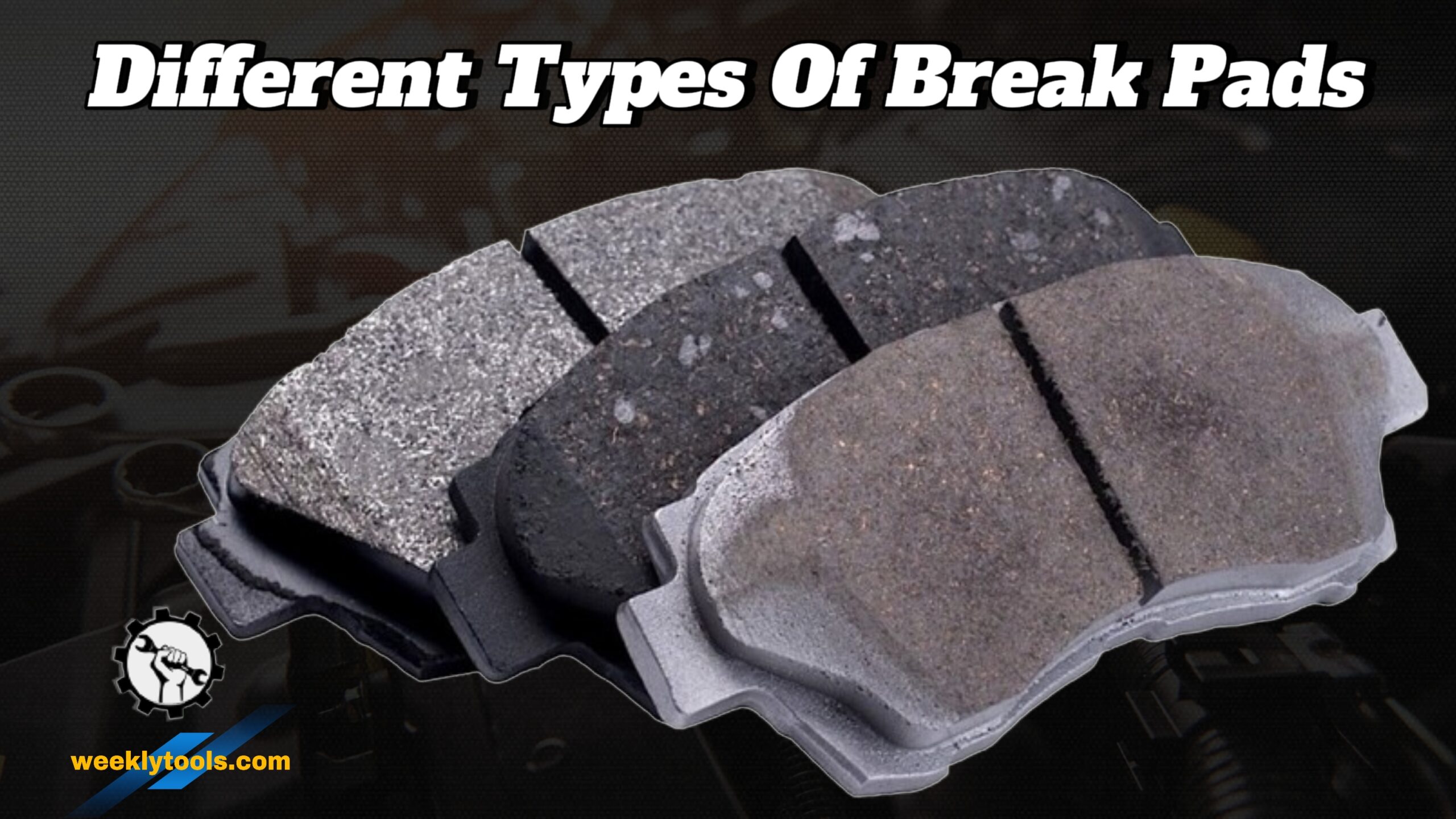

Different Types of Brake Pads

The market offers various types of brake pads, each with its own set of characteristics, advantages, and drawbacks. They actually have different specifications, functionalities, and technical aspects that you may consider to choose the best suitable one for your vehicle.

Non-Metallic (Organic) Brake Pads

Non-metallic or organic brake pads are characterized by their softer composition, consisting of a blend of glasses, rubbers, resins, and occasionally metal fibers. Originally, asbestos material was used in these pads, but due to health concerns, modern versions are constructed from alternative compounds. These pads are standard on approximately 67% of new vehicles sold in the United States.

Materials: Mixture of fibers, rubber, carbon compounds, glass or fiberglass, and sometimes even Kevlar. The actual composition may vary to manufacturers and products.

Performance: Generates a moderate amount of friction without much heat, suitable for everyday driving and commuting.

Advantages

Produce less noise, generally quieter less stress on brake rotors Products are generally available at a lower price point.Disadvantages

Wear out more quickly due to their composite nature less effective in extreme temperatures higher compressibility requiring more force on the brake pedalIdeal for: urban commuting and daily road driving.

Replacement Frequency: May need more frequent replacement due to accelerated wear.

Semi-Metallic Brake Pads

Semi-metallic brake pads, found in the majority of cars today, utilize a combination of synthetics and metals to create a predominantly metallic hybrid compound. The metal content, ranging from 30% to 70%, includes copper, iron, steel, and other composite alloys. Today, semi-metallic brake pads refer to metallic brake pads. Pure metallic brake pads no longer exist.

Material Composition: Blend of synthetics and metals (copper, iron, steel). The exact proportion may vary to each manufacturer and product.

Performance: Offers improved braking performance in a comprehensive range of temperatures and conditions.

Advantages

Resistant to heat and wear Better thermal conductivity Suitable for heavy braking situations, Versatile applicationsDisadvantages

Slightly more pedal power required when cold Potential for noise and more brake dustIdeal for: A wide range of driving conditions, including high-performance and heavy vehicles.

Ceramic Brake Pads

Ceramic brake pads, introduced in the mid-1980s, are made from a ceramic compound similar to that used in pottery. This material is denser and more durable, with fine copper fibers embedded to enhance friction and heat conductivity.

Materials: Denser ceramic compound with embedded copper fibers.

Performance: Very quiet, produces less dust, reliable in a broad range of temperatures and driving conditions.

Advantages

Excellent heat absorption minimal noise reduced dust productionDisadvantages:

Higher manufacturing costs, slower to warm up in daily driving conditions.Ideal for: High-performance sports cars and situations requiring continuous, intense braking.

Choosing the Right Brake Pad for You

The choice between non-metallic, semi-metallic, and ceramic brake pads depends on various factors, including your vehicle’s manufacturer recommendations, driving style, and intended application.

Non-Metallic(Organic) Brake Pads: Suited for daily commuting and road driving, cost-effective but may require more frequent replacement. Semi-Metallic Brake Pads: Versatile and suitable for various driving conditions, ideal for high-performance and heavy vehicles. Ceramic Brake Pads: Best for high-performance sports cars, offering excellent heat absorption and reduced noise.Remember to adhere to recommended replacement intervals, and consult your brake pad manufacturer for specific guidance based on your driving habits.

Therefore, understanding the characteristics and considerations of different brake pad types allows you to make an informed decision based on your vehicle’s needs and your driving preferences. Whether you prioritize longevity, performance, or a balance of both, the right brake pad choice contributes significantly to your vehicle’s safety and stopping power.

How To Tell You Need A New Brake Pad

As a critical component of your vehicle’s braking system, brake pads undergo gradual wear over time, necessitating timely replacement to ensure optimal performance and safety. Modern brake pads are equipped with wear indicators designed to alert drivers when replacement is imminent. Understanding these signs is crucial for maintaining the effectiveness of your braking system and preventing potential damage. Here are some key indicators that it’s time for new brake pads, along with detailed explanations:

1. Screeching Sound When Braking

Brake pads feature wear indicators, typically made of a soft metal. When the friction material of the brake pad wears down, the wear indicator makes contact with the brake rotor, producing a high-pitched screech or squeal. This audible warning signals the need for brake pad replacement.

2. Persistent Noises

Persistent grinding or squealing noises while driving can indicate advanced wear on the brake pads. As the friction material diminishes, the metal backing of the brake pad may come into contact with the brake rotor, resulting in these audible warning signs.

3. Longer Distance for Stopping

A noticeable increase in stopping distance is a clear sign that the brake pads have worn down. Reduced friction between the pads and the rotor diminishes the braking efficiency, requiring a longer distance to bring the vehicle to a complete stop.

4. Vibrations on Brake Pedal

Pulsations or vibrations felt through the brake pedal during braking may suggest uneven wear on the brake pads. This uneven wear can lead to an inconsistent braking experience and is often indicative of the need for replacement.

5. Delayed Return Brake Pedal

Explanation: If you observe that the brake pedal sits lower to the floor than usual, it may indicate significant wear on the brake pads. This reduction in pedal height reflects the diminished thickness of the brake pad material, necessitating prompt replacement.

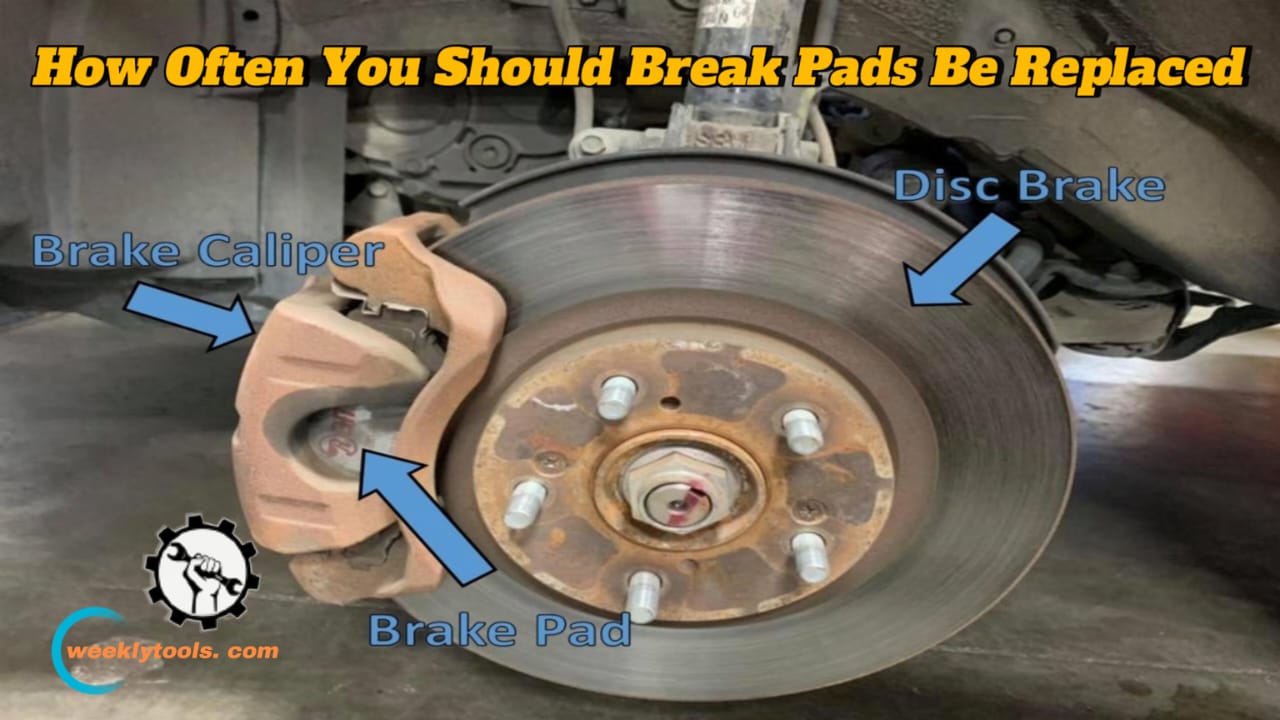

When and How Often Should Brake Pads Be Replaced?

Sooner or later, you’d need to replace the brake pad following the wear and tear. However, the frequency of brake pad replacement depends on factors such as driving habits and the vehicle’s usage. General guidelines suggest replacement every 20,000 to 60,000 miles, but individual circumstances may vary.

Brake pads incorporate wear indicators, such as a soft piece of metal that creates a screeching sound when in contact with the brake rotor. Ignoring these signs can lead to further damage, necessitating more extensive and costly repairs. Compatible brake pads are necessary when it comes to replacement.

During a brake pad replacement, technicians typically go beyond pad inspection. They measure the thickness of brake rotors, check for signs of wear, abrasion, and damage on the brake disc, and assess brake fluid levels in the reservoir. A comprehensive check ensures the overall health of the braking system.

Brake Pad Replacement Cost Estimation

The cost of a brake pad replacement varies based on the car model and potential additional work. On average, customers may typically spend between $150 and $400 for a brake pad replacement, inclusive of parts and labor. While some may opt for a DIY approach, professional technicians ensure optimal brake performance.

FAQs

1. What distinguishes brakes from brake pads?

The primary distinction between brake shoes and brake pads lies in the direction of force they exert. Brake shoes bring the vehicle to a halt by pushing outward, while brake pads achieve this by moving closer together. Unlike brake shoes situated inside a brake drum, brake pads are positioned around a disc known as a rotor.

2. How can I tell if my brake pads are worn?

Worn brake pads often manifest through various signs. You may experience screeching noises while braking, noticeable vibrations, or your car pulling to one side when applying the brake pedal. Additionally, an extended braking distance, where it takes longer than usual for your brakes to slow the vehicle down, is indicative of worn brake pads. A warning light on your dashboard will also alert you to any issues related to wear and tear.

3. When do I need to replace brake pads or calipers?

While brake pad and brake rotor replacement is a routine maintenance task, replacing calipers is less common. Typically, calipers only need replacement when damaged or when the pistons fail to extend after braking. It is advisable to replace pads and rotors with every brake job, ensuring optimal braking performance.

4. What steps should I take immediately after changing brake pads?

Following the installation of new brake pads, it is recommended to make 6 to 10 stops from approximately 35 mph with moderate pressure. Additionally, perform two to three hard stops from around 40 to 45 mph. Avoid allowing the vehicle to come to a complete stop during this process to optimize the seating of the new brake pads.

5. Is brake bleeding necessary after changing brake pads?

Yes, bleeding the brakes is advisable after changing brake pads, especially if you are replacing worn pads. Worn pads can allow air to enter the master cylinder, and braking with them requires more brake fluid, leading to reservoir drainage and the potential introduction of air into the system. For safety reasons, any brake job, including pad replacement, should include a brake bleed to ensure optimal brake performance.

Brake pads are the unsung heroes of the road, silently stopping your car with the power of friction. They convert your car’s kinetic energy into heat, scrubbing against the brake rotors like a tiny, fiery eraser. This crucial duo keeps you safe, so next time you hit the brakes, remember the little pads working tirelessly behind the scenes.