By Zac Yates One of two projects to return the oft-maligned �Tiffy� to the sky (the other being centered around RB396 in the UK) Typhoon Legacy Co Ltd�s Mk.Ib JP843 was originally built with the [...]

By Zac Yates

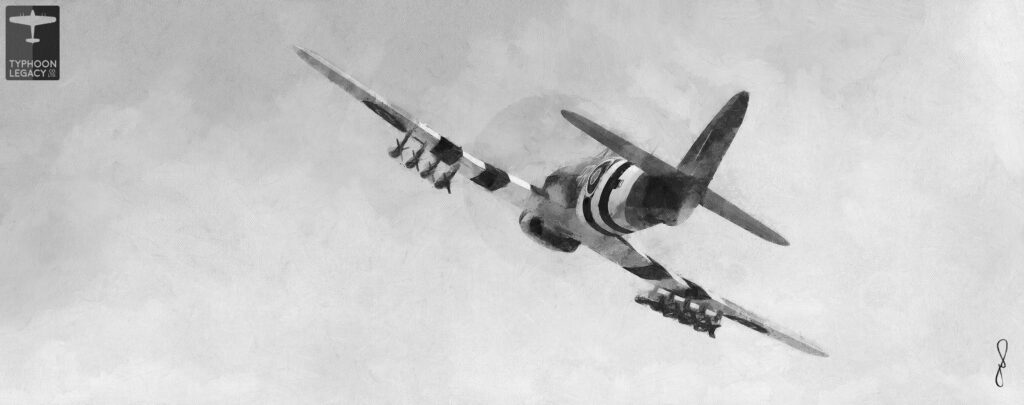

One of two projects to return the oft-maligned �Tiffy� to the sky (the other being centered around RB396 in the UK) Typhoon Legacy Co Ltd�s Mk.Ib JP843 was originally built with the early �car door�-style canopy and was delivered to 197 Squadron RAF at Tangmere on 22 September 1943. After being damaged in combat with Focke-Wulf Fw-190s on 3 January 1944 the aircraft was repaired and modified with the new bubble canopy and provision for rocket armament. Later allocated to 609 Sqn, it was shot down on a ground attack mission near Poussy-la-Campagne in France on 27 July 1944, killing Pilot Officer Peter March Price RNZAF. Previously the subject of a cockpit restoration by Roger Marley in the UK the aircraft was acquired by Typhoon Legacy in 2015 and moved to a dedicated workshop in Comox, British Columbia where restoration to airworthiness was begun.

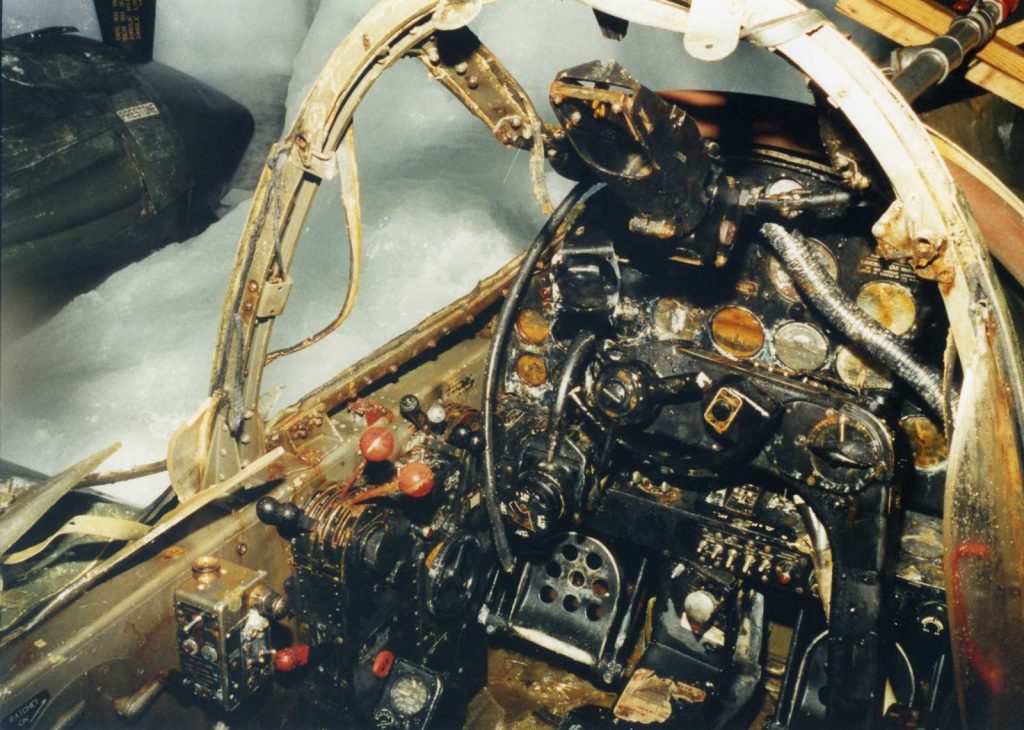

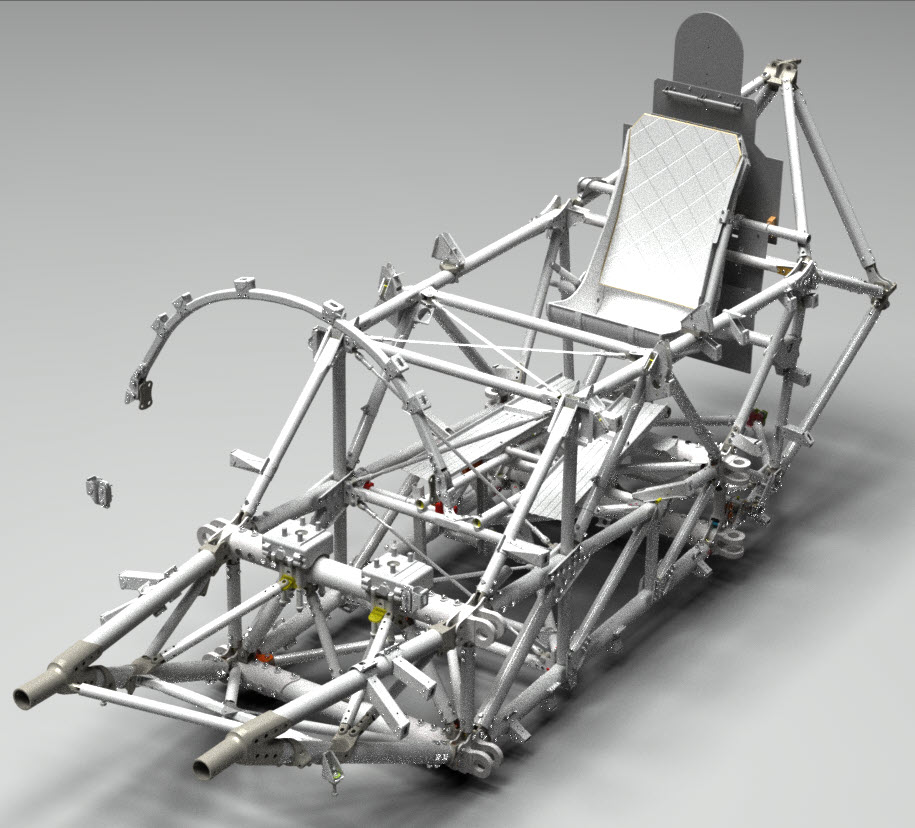

JP843 project lead Ian Slater had already spent much of his life working toward achieving the goal of a flying Typhoon as a tribute to those who worked on and flew the type, including training as an aircraft maintenance engineer (specializing in sheet metal fabrication) and gathering original technical drawings. Earlier this year the team acquired a Napier Sabre from New Zealand in exchange for a restored Rolls-Royce Merlin, and much work has already been done to produce the rear fuselage monocoque and distinctive chin radiator fairing. Their current focus is the cockpit section, which Ian said was a complex assembly that required outside help and a lot of preparation.

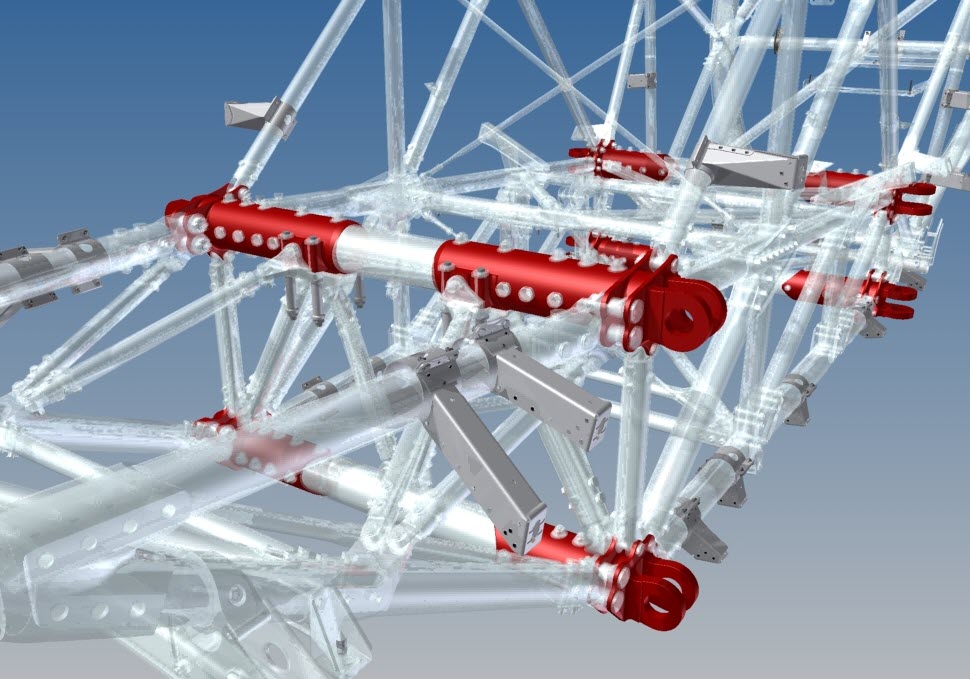

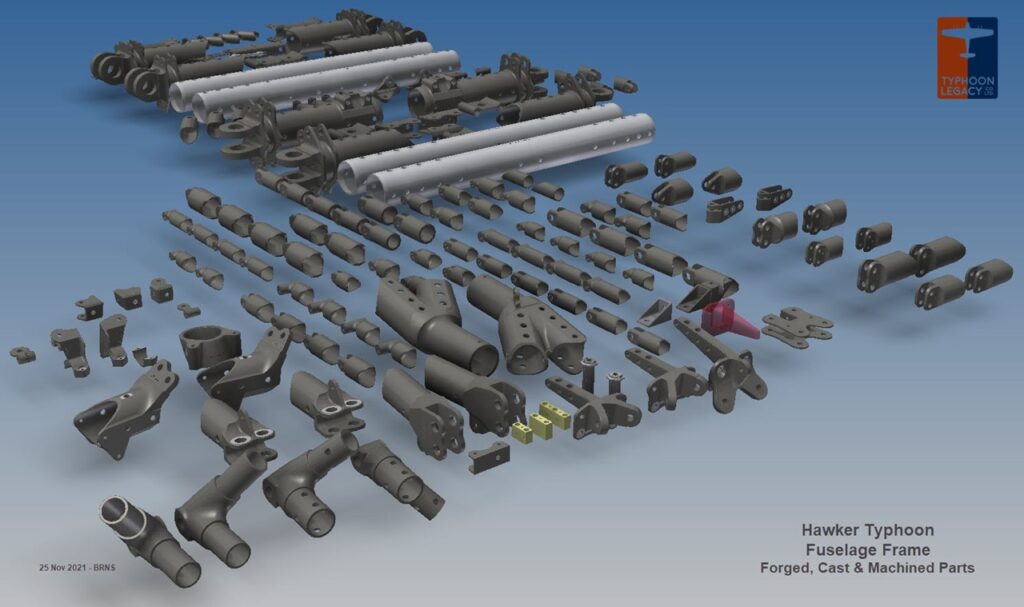

�The cockpit structure is the center of the aircraft to which every main component is attached; starting construction of this section will first require the manufacture of the main spar fittings. Construction for this area is the cumulation of approximately 7 years of research, reverse engineering, CAD design, and material acquisitions,� said Slater.

�Work on the spar fittings started many years ago with the reverse engineering of our surviving examples (at no cost) by our sponsor E3D Technology. With the geometry captured, the digital models were used as the basis of our cockpit design and component verification process. The CAD work on this section alone represents many thousands of hours. With the complexity of these parts, we have had to outsource the machine work to a company with specialized equipment. Costs for this process on all eight fittings will be $45,000 in Canadian funds. The necessary material has been purchased and delivered, and we have made a down payment of $8000 to get started.�

On December 22 the team kicked off a fundraising effort to finance the all-important fittings with several donation tiers, including large format prints of Typhoon JP843 artwork by noted aviation illustrator David Bathe � measuring 95cm (37in) � and the opportunity for donors to have their name on the aircraft�s airworthy port cockpit panel.

In the first 12 hours, donations had reached CAD$18,880 � 42% of the fundraising target. �I�m amazed and so very thankful for everyone that has contributed to this fundraiser,� Ian said.

�This project has been my life�s focus, I�ll never be able to thank those who believe in my dreams and the skills of our team here at Typhoon Legacy to the extent that they deserve. We�ve made a big dent in our goal within the first 12 hours and if we can keep this going we will see a cockpit being put together before you know it! My sincerest thanks to everyone!�

Donations can be made via PayPal at this link, and should a donor prefer to contribute through other means Typhoon Legacy can be contacted directly via their website at https://www.typhoonlegacy.com/. The project can also be followed on Facebook at https://www.facebook.com/hawkertyphoonjp843/.