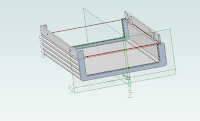

I have been busy with some other things that have kept me away from electronics projects for quite a while. Now I can get back to them, but realize I need some boxes to put them in. I have 3D printed some simple ones a while ago, I will redo the design to make them fit the way I have been building my projects now. Most of my designs use modules that I etch or route. For these I buy copper clad boards that are usually 100 mm wide. This is one of the standard widths availibale cheaply through eBay or other suppliers. One standard size I use is 100 x 70 mm. Going with that as a default I designed a clam shell case, that has two identical parts, that you join together with a few screws. I want to be able to simply add modules without having to drill holes in the case. To do this I designed the case half with slots to slide the modules in vertically. After printing a set of these I decided to also design another without the slots to use as a top, which makes it easier when trying to aligning multiple modules. I decided on 7 internal slots for modules, along with slots on the ends for front and rear panels. I also made versions in three heights, mixing different height versions I could get an inside height from 40 to 80 mm. in 10 mm steps.I also made a set that fits one of the standard 50 x 70 mm perf boards I use sometime. This one only has 4 internal slots long with the ones on the ends.I made the mounting holes to fit 3 mm screws. They are tight but I was able to self tap without too much problem. Depending on printer settings and filament I might have to run a drill bit or a tap through the holes to clean them up.For those interested I have added the .stl files to the dropbox I have for the storage boxes from a previous post.https://www.dropbox.com/sh/webi4nhd1a6kd6f/AAArBUSR40y3TQSZBHt8w-Cja?dl=0

I have been busy with some other things that have kept me away from electronics projects for quite a while. Now I can get back to them, but realize I need some boxes to put them in. I have 3D printed some simple ones a while ago, I will redo the design to make them fit the way I have been building my projects now. Most of my designs use modules that I etch or route. For these I buy copper clad boards that are usually 100 mm wide. This is one of the standard widths availibale cheaply through eBay or other suppliers. One standard size I use is 100 x 70 mm. Going with that as a default I designed a clam shell case, that has two identical parts, that you join together with a few screws. I want to be able to simply add modules without having to drill holes in the case.

|

I also made a set that fits one of the standard 50 x 70 mm perf boards I use sometime. This one only has 4 internal slots long with the ones on the ends.

I made the mounting holes to fit 3 mm screws. They are tight but I was able to self tap without too much problem. Depending on printer settings and filament I might have to run a drill bit or a tap through the holes to clean them up.For those interested I have added the .stl files to the dropbox I have for the storage boxes from a previous post.

https://www.dropbox.com/sh/webi4nhd1a6kd6f/AAArBUSR40y3TQSZBHt8w-Cja?dl=0